Others

Thordon Rudder Bearing

Concept

- Thordon Rudder Bearings are made of homogeneous, elastic bearing material that is composite of rubber and resin.

- They are excellent in abilities of elongation and shape restoration; have a low friction coefficient; and are rich in abilities of pressure-resistance, abrasion-resistance and corrosion-resistance.

- Even in an extremely polluted environmental condition, smooth and long life operation is possible without lubrication such as grease, oil, etc

- It is an ideal rudder bearing even in terms of freedom from water pollution concerns as only water lubrication is pardonable.

Special Features

- It is excellent in abrasion-resistance, and extremely long wear life.

- It can endure high bearing pressure.

- It has a low coefficient of friction, and can reduce a power loss.

- It is elastic, endures high impact load, and absorbs vibration.

- It is extremely light in weight (about one-sevenths of bronze material).

- It can be easily machined.

- It is free from layer separation, which is seen in such bearings as phenol-resin layer bearings.

- It can be easily mounted by means of making it shrink, using dry ice or liquefied nitrogen.

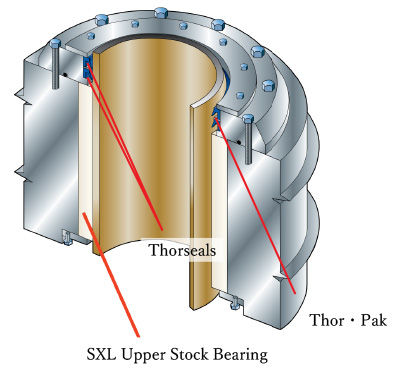

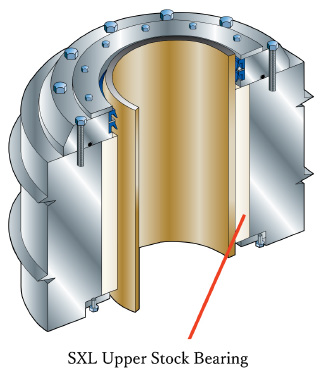

- Thordon SXL Type Bearings are self-lubricative and capable of dry operation.

Accordingly, they can omit a burdensome lubrication system.

Advantages and Special Characters in Equipping

-

By virtue of a low coefficient of friction and a self-lubricative property of Thordon Bearings, steering torque is reduced, and smooth rudder operation is capable.

-

By virtue of water lubrication, instead of grease lubrication, no grease consumption and no water pollution are brought. Furthermore, construction cost is significantly reduced since a rudder sealing system, a grease injection pump and their appendant piping, oil hole drilling, oil grooving, etc. are omitted.

-

Preparation of an expensive hydraulic jack for mounting a bearing is not necessary, and danger at lifting a bearing can be avoided, and furthermore, omission of pipe joint flanges, saving of mounting time, and safe and light work, etc. greatly contribute to saving of cost directly and indirectly.

-

Less influence of foul water is exerted on a Thordon Bearing, and it keeps longer than bronze, nylon or phenol materials. Furthermore, it is adaptable to local load, and its low friction reduces adhesive abrasion. In addition, even in case of such an accident that a bearing is dropped from dock staging, it will never be damaged.

-

A Thordon Bearing can be finely machined without emitting any dust and gas, only with elastic thread-like pieces being exhausted. A Thordon Bearing is a nonmetallic bearing with no ingredients of asbestos and chemical matter that cause physical trouble at machining.

-

A Thordon SXL Type Bearing is optimum for a high load rudder bearing that involves risk of adhesive abrasion in a dry condition.

-

A Thordon Bearing effectively diffuses load by micro deflection, and reduces locally high contact pressure of a bearing. Accordingly, it can avoid wiping (molten separation by high temperature) of a bearing.

-

A Thordon Bearing is light in weight, one-sevenths of bronze weight, and can reduce ship weight with level of 1,000kg, compared with bronze bearings.

-

Thordon Bearings are approved by major Classification Societies.

As allowable contact pressure of a rudderstock bearing according to NK Regulation, it is approved for a Thordon SXL Type Bearing to be usable with 10N/mm2(7N/mm2 for a bronze bearing).

Wear Life Guarantee

15-YEAR NEW BUILD

GUARANTEE & UP TO

10 YEARS IN CONVERSIONS

- Better Performance

-

Thordon SXL has a lower modulus of elasticity (440 MPa or 68,817 psi) than other non-metallic bearings, resulting in significantly increased vibration dampening, accommodation of edge loading, and better impact resistance than other non-metallic materials.

- Industry-leading wear life guarantees

- Tolerance to edge loading

- Wet or dry operation eliminates the use of grease

- Transient shock loading absorption

- High abrasion resistance

- Quick delivery

- Easy to Machine & Fit

-

Thordon SXL bearings are easy to machine and produce no dust.

In comparison, other non-metallic materials require dust extraction and tight machining tolerances that may result in product rejection or repair delays.

With Thordon SXL, machining tolerance is less critical and because of the relatively large interference on the bearings, it is usually possible to adjust dimensions to compensate for small machining errors.

15-Year Rudder Bearing Wear Life Guarantee*

Thordon’s 15-Year Rudder Bearing Wear Life Guarantee ensures provision of a replacement if a Thordon SXL rudder bearing wears out and requires renewal before the 15 year period is up.

Newbuilds

The guarantee covers pintle, rudder stock, and carrier disc bearings above and below the waterline in Classed newbuild vessels. It applies to the original owner of the ship and is nontransferable. Engineering details such as Classification Society, vessel name, shipowner’s name, and rudder specifications will be required prior to issuing the guarantee.

Conversions

In conversion pintle, stock, or carrier disc applications, Thordon SXL rudder bearings are guaranteed to meet Classification Society wear specifications for twice the life of the non-Thordon bearing replaced, up to a maximum of ten years, or Thordon Bearings will supply a new rudder bearing free of charge.

*The guarantee is subject to prior approval by Thordon Bearings Inc. and limited to the supply of replacement bearings.

*Certain conditions may apply. Please contact

Thordon Bearings Inc. for further information.